Service

Piping

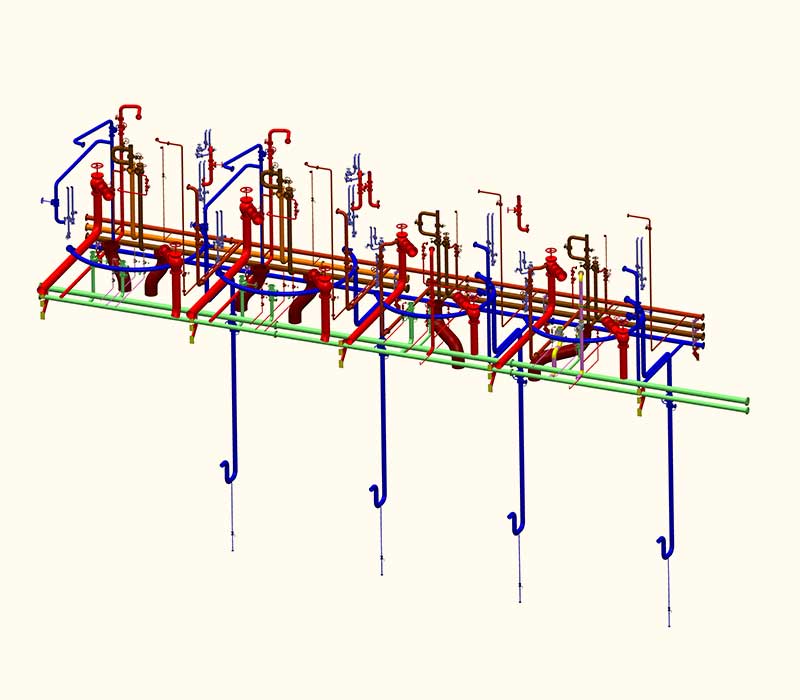

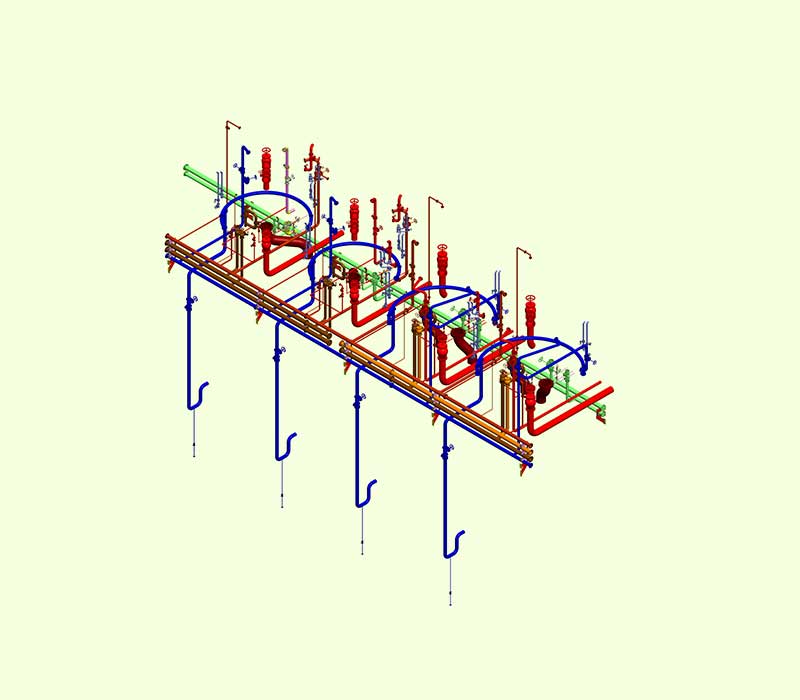

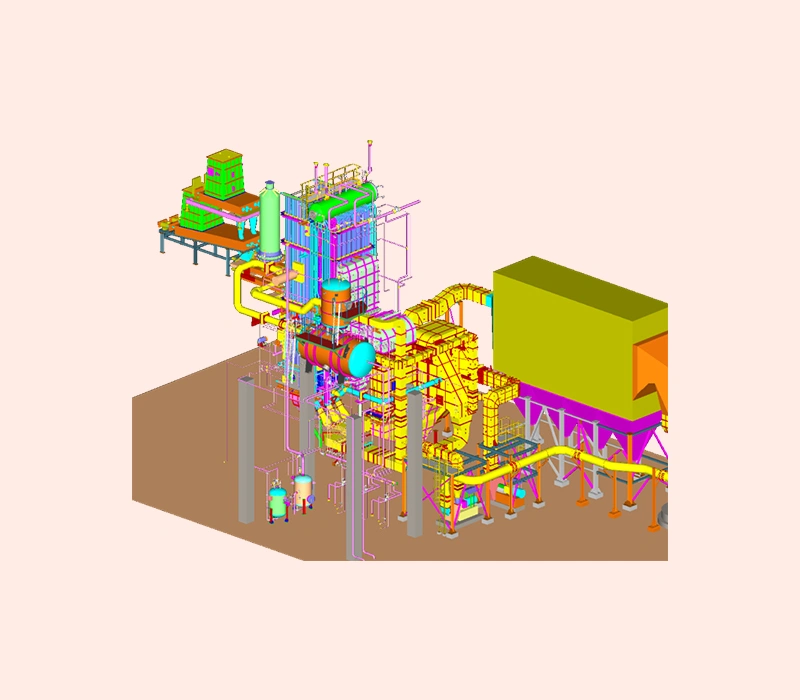

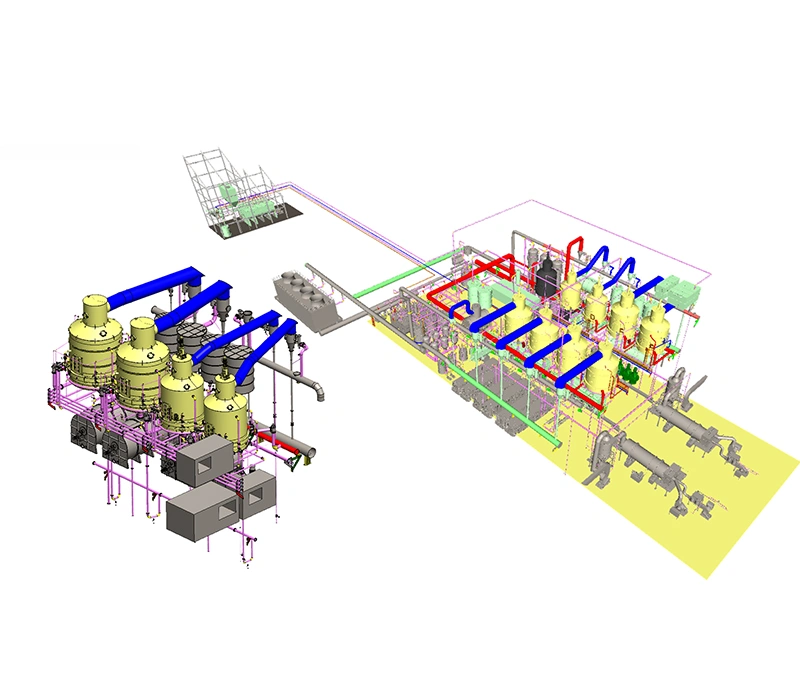

Piping design engineering 3D Modelling and Design

With a strong foundation in industrial engineering, we specialize in providing comprehensive solutions for piping systems across various industries. Our team brings together years of experience and technical proficiency to deliver reliable, efficient, and cost-effective piping solutions tailored to meet the unique needs of each project.

Partner with us for your piping engineering and design needs and discover the transformative impact of our expertise.

Initial Requirements Analysis

- The first step is to gather all relevant information about the project, including process requirements, equipment layouts, regulatory requirements, and safety considerations.

Piping Layout Design

- Based on the P&IDs and other project requirements, piping designers develop a preliminary piping layout.

- This involves determining the optimal routing of piping systems to ensure efficient operation, accessibility for maintenance, and compliance with safety standards.

Material Selection

- Selecting appropriate materials for piping components is essential to ensure compatibility with the process fluids, temperature, pressure, and environmental conditions.

- Factors such as corrosion resistance, mechanical properties, and cost are considered during material selection.

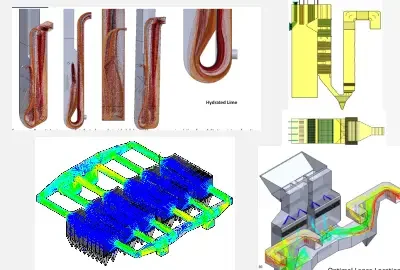

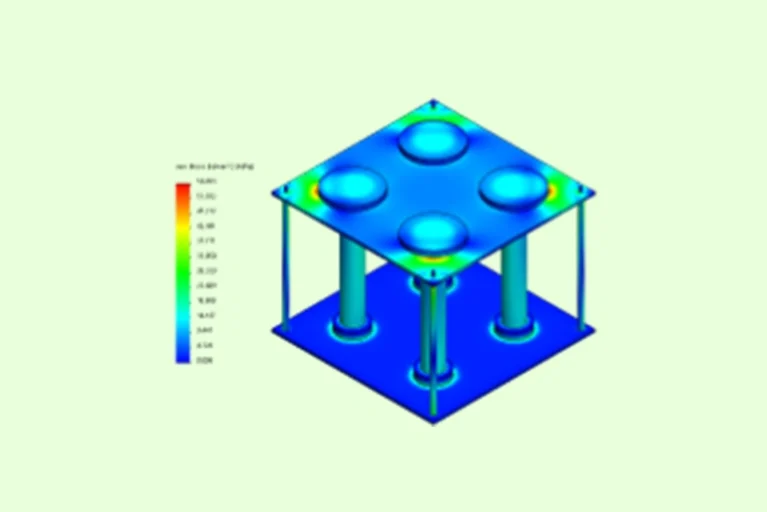

Stress Analysis

- Piping systems must be designed to withstand various loads, including pressure, thermal expansion, vibration, and seismic forces.

- Finite Element Analysis (FEA) and other computational tools are used to analyze the stresses and deformations in the piping system to ensure structural integrity.

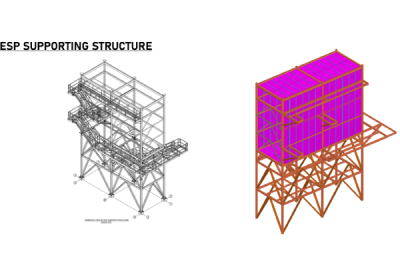

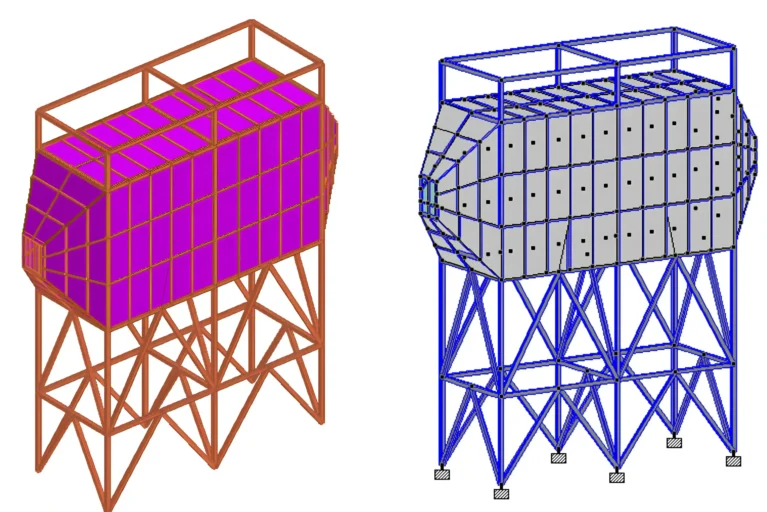

Support Design

- Proper support and restraint of piping systems are critical to prevent sagging, vibration, and excessive stress.

- Piping designers specify the type and location of supports, hangers, and anchors based on the piping layout and stress analysis results.

Pipe Sizing and Specification

- Piping designers determine the appropriate pipe sizes for different sections of the system based on.

- Fluid flow rates, pressure drop calculations, and other factors.

- They also specify the type of fittings, valves, and other components required for each section of the piping system.

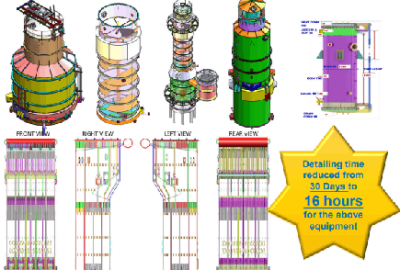

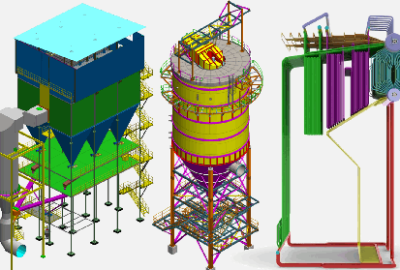

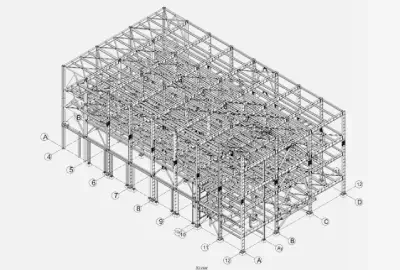

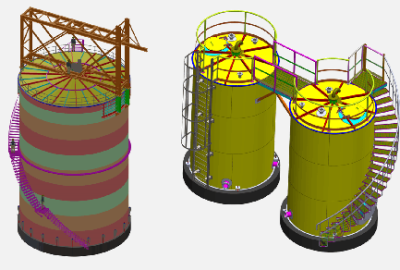

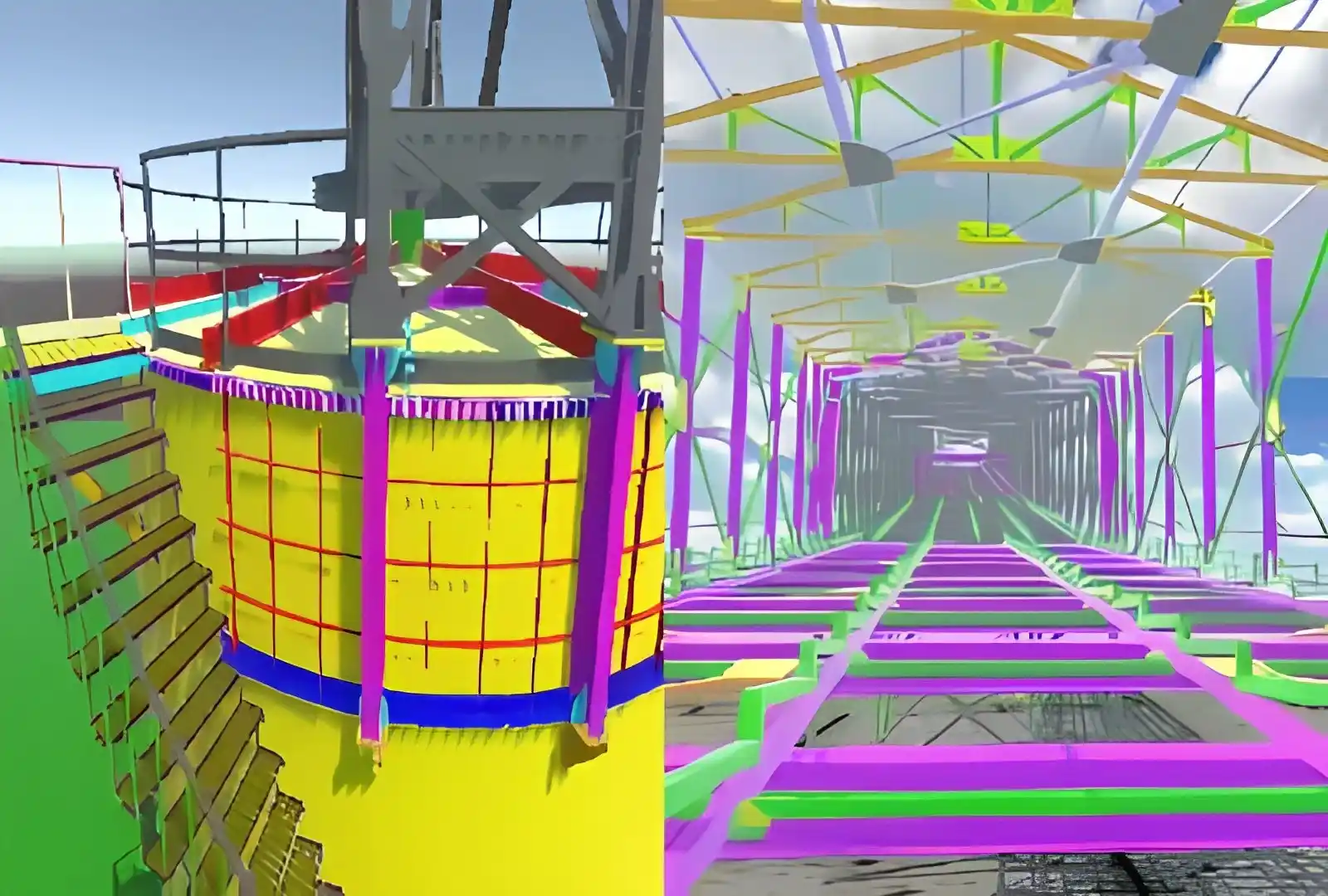

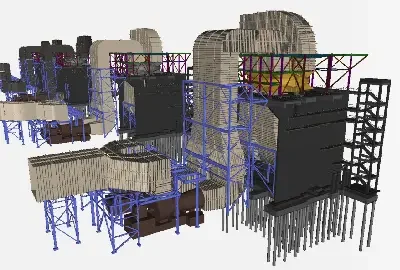

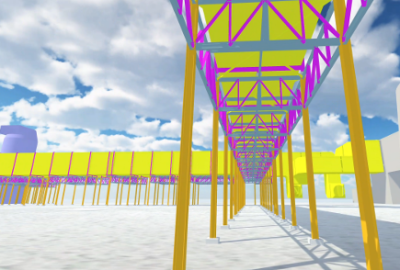

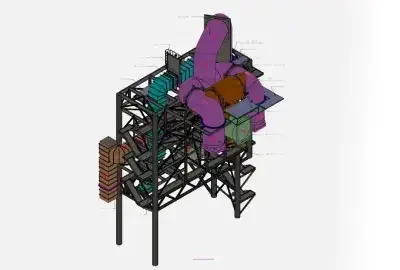

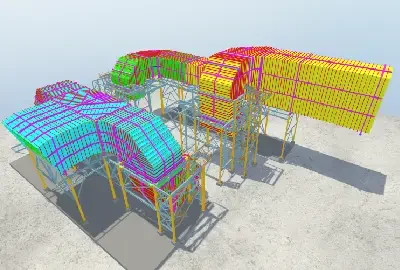

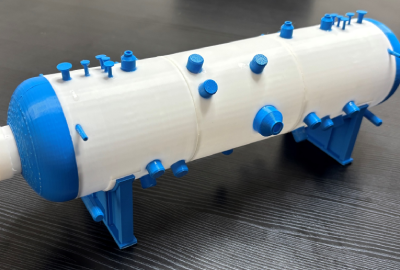

3D Modelling

- Advanced piping design software is used to create detailed 3D models of the piping layout.

- These models provide a visual representation of the entire system, allowing designers to identify clashes, optimize routing, and visualize the installation sequence.

Documentation

- Detailed drawings, including plan views, elevations, isometric views, and piping isometrics, are generated from the 3D models.

- These drawings provide contractors with the information needed to fabricate, install, and test the piping systems.

Review and Approval

- The final piping design is reviewed by project stakeholders, including engineers, designers, and clients.

- To ensure that it meets all project requirements, safety standards, and regulatory codes.

- Any necessary revisions are made before obtaining final approval.