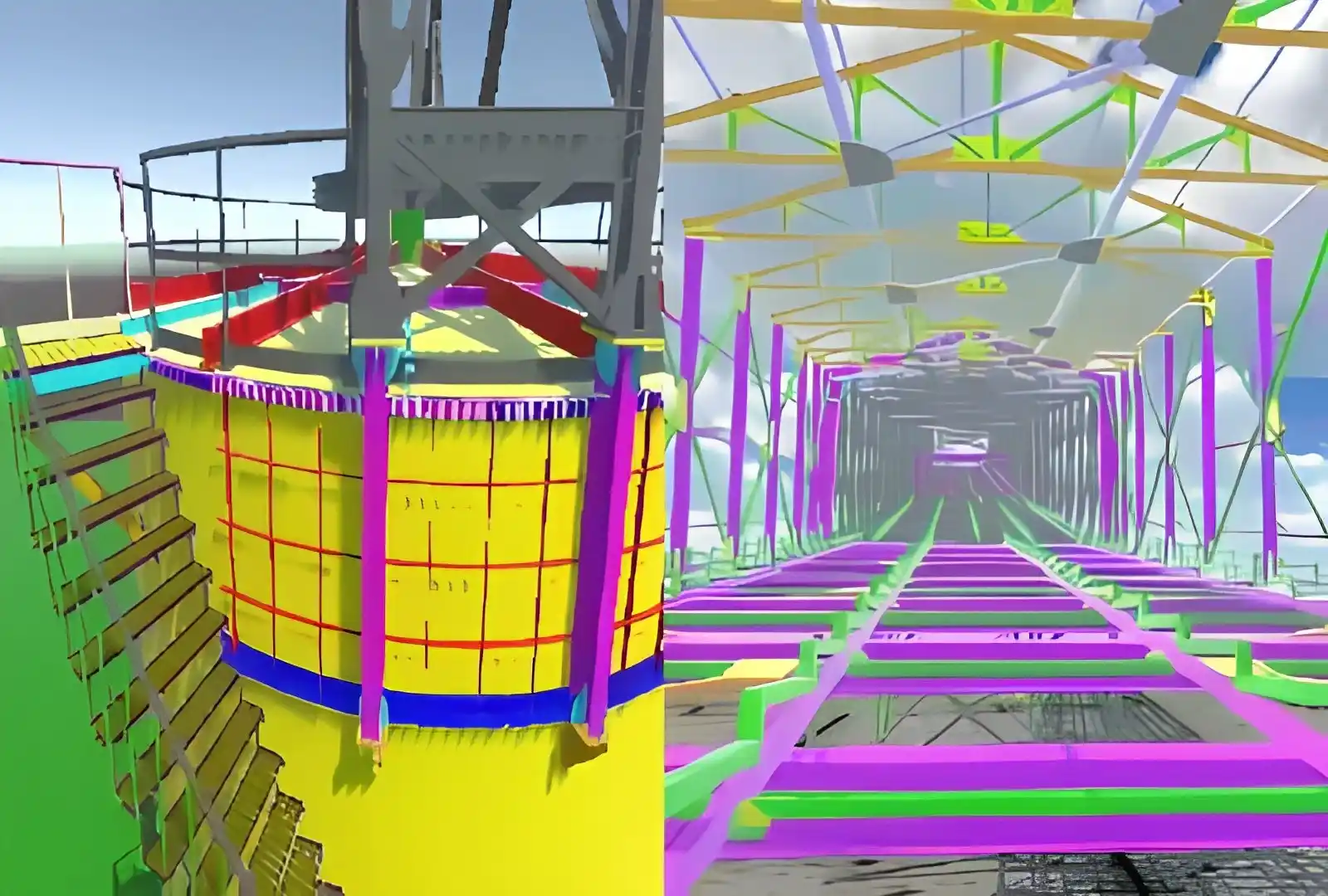

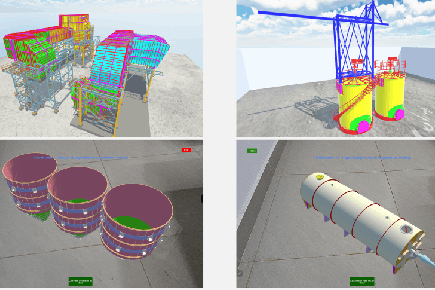

We provide best Industrial Engineering Design, and Walkthrough Animations.

Our Clients

TRUSTED BY FORWARD-THINKING ENGINEERING TEAMS AROUND THE WORLD

09+ years of experience working in the country’s main industrial sectors.

We are always open for cooperation and welcome new interesting projects. Contact us in any way convenient for you.

Work Process

For the last 09+ years, we have been seeking out challenges that will allow us to learn and be better at what we do.

2025

Bellary FGD for 1700 MW. Raichur FGD for 7x210+1x250 3D Printing capability integrated.

2024

Automation of Fabrication Drawings for Boiler Pressure Parts. Digital Twin-based piping design and detailing for process plants. Released fabrication drawings for 50,000 Tonnes extracted from 3D modeling, all erected seamlessly without field clarifications.

2023

ESP Physical Flow Model for Mejia 3 x 210 MW, Dry Sorbent Injection for 210 MW, FGD projects for 1200 MW

2022

AR & VR Project from DIO-IDEX(DISC6 – Indian Navy), FGD projects for 1700 MW, Battery analysis for Defence Projects, Exxon Mobil Oil & Gas Project.

2021

ESP Physical Flow Model for Anpara 500 MW Power Plant – FGD projects for 7000 MW, Design Automation Projects.

2020

FGD Projects for 4500 MW – Semi Dry FGD Project, Design Automation Projects.

2019

Defence Projects, Design Automation, Flue Gas Desulphurization Projects for 2260 MW.

2018

India’s first private ESP Physical Flow Model for Farakka 500 MW Power Plant.

2017

Formation of TryCAE, NTPC & NPCIL Pipe Supports Design.

There are many factory in city but why should you choose our products?

0

+

Projects

1

+

CLIENTS

1

+

ENGINEERS

1

+

OFFICES

USP’s (Unique Selling Proposition) of TryCAE

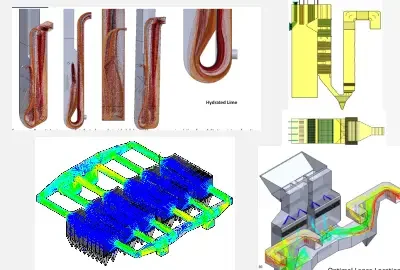

Experimental Fluid Dynamics Expertise:

Only Indian company conducting Experimental Fluid Dynamics projects for ESPs and Boilers.

CFD/FEA:

International Expertise in CFD/FEA domain

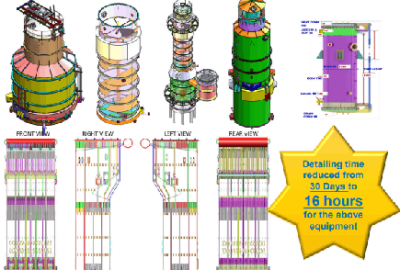

Design Automation Excellence:

Reduced fabrication drawing lead time from 30 days to 2 days with automation.

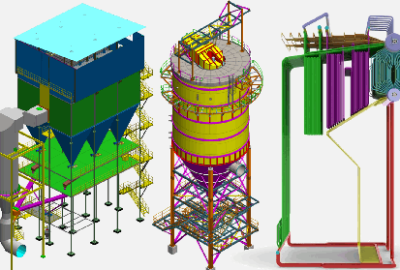

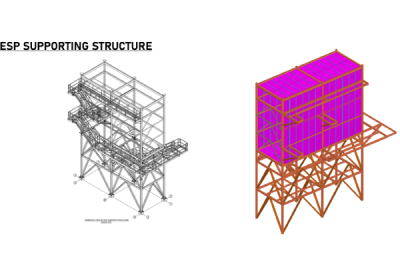

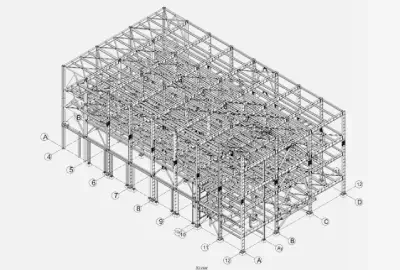

3D Model-Driven Design:

Utilizing 3D models across all design phases with fabrication drawings and BOM extracted from 3D Model.

FGD Project Expertise

Executed Engineering Services for 25,000 MW of Flue Gas Duct projects.

Error-Free & Erection Ease Fabrication Drawings:

Supplied 50,000 Tonnes of fabrication drawings and erected without site queries.

Integrated Engineering Solutions:

Only company in India offering 3D Modeling, CFD, FEA, Digital Twin, AR & VR under one roof.

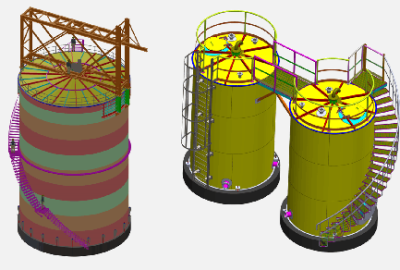

Tank Engineering:

Executed Engineering services for 7,350 MW of Power Plant Tanks.

Certified Professionals:

Workforce accredited by Dassault Systemes, with 50% holding Master's degree.

Employee-Centric Approach:

Fostering growth with education support and a supportive grow together working culture.

Social Responsibility:

Empowering engineering students by bridging gap between industry and academia.

Mission Statement